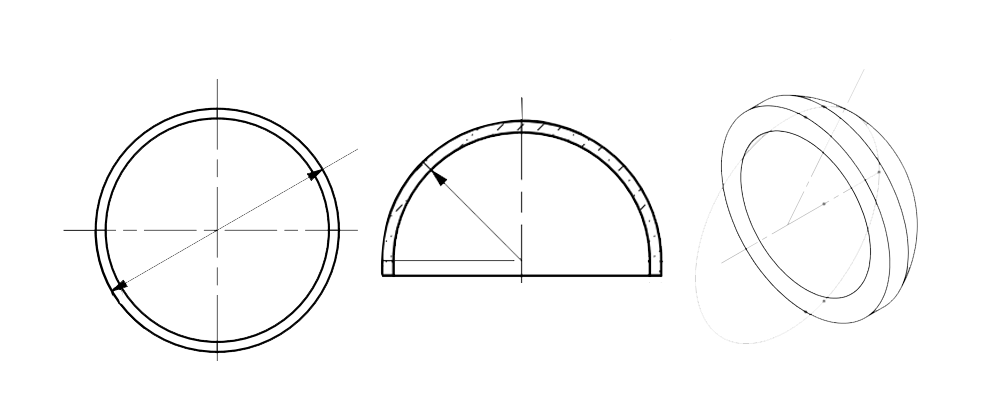

An optical dome is a type of lens with two concentric spherical surfaces, typically used to protect precision instruments and equipment, especially in harsh environments. The main function of the optical dome is to safeguard the internal optical components from external environmental damage while ensuring that the performance of the optical system remains unaffected.

The optical dome and optical window both protect optical systems but differ in design and applicat.

Optical Dome: Spherical or hemispherical, providing uniform protection in all directions. Used in harsh environments like diving equipment and drones. Requires precise design due to light refraction and scattering, making it costlier.

Optical Window: Flat, offering planar protection for devices like camera lenses and sensors. Minimal impact on optical performance and simpler, cheaper manufacturing.

In summary, the choice depends on specific needs and conditions, with key differences in shape, application, optical performance, and manufacturing complexity.

Item | Commercial | High precision |

Substrate | UV material: Fused silica ( 7980, JGS1, etc.) VIS material: Optical glass ( BK7, BK10, H-K9L), IR material: Silica crystal, Sapphire | |

Diameter | Ø10mm – Ø70mm | |

Diameter tolerance | ±0.1mm | ±0.03mm |

Thickness | 1.5mm-5mm | |

Thickness tolerance | ±0.1mm | ±0.05mm |

Surface quality | 60/40 | 20/10 |

Field angle | 120°-180° | |

Fringe | 10(5) | 3(0.5) |

Coating | Upon customers’ request | |

The manufacturing process of an optical dome includes the following steps: selecting high-transparency materials (such as optical glass, quartz, sapphire), rough machining to shape, using a spherical grinder to generate concentric spherical surfaces, fine polishing to achieve optical quality, using high-precision equipment for inspection and calibration, applying coatings (such as anti-reflective or reflective coatings), cleaning and assembling into the optical system, and finally conducting overall performance testing. The entire process requires high-precision equipment and strict quality control.

Optical domes are widely used in various fields, including aerospace (missiles, drones, satellites), marine exploration (diving equipment, underwater robots), military defense (missile guidance, night vision devices), meteorological observation (satellites, ground equipment), medical devices (high-end imaging), industrial automation (robots, inspection equipment), scientific research (astronomical telescopes), and consumer electronics (high-end cameras). Their unique shape and excellent optical performance provide comprehensive protection and high light transmission.

Translation: Optical domes are typically made from optical glass, quartz, sapphire, plastics, and other special materials. Optical glass and quartz offer high light transmission, sapphire provides high hardness and wear resistance, while plastics like polycarbonate and acrylic are lighter and cost-effective. Material selection depends on requirements for light transmission, durability, and environmental adaptability.

If you would like to build your own precision optical products or request a quote, please click one of the two buttons below. Otherwise, please fill out the form below with any questions or concerns.

Address

B3 Shengshi Shengshi Industrial Park,Auto-ETDZ, Changchun, Jilin, China

Call Us