Dielectric mirrors can achieve extremely high reflectivity (exceeding 99.8% in the designed wavelength range), primarily used to minimize losses when reflecting laser beams and other light sources. Absorption and scattering during reflection can lead to flux reduction and potential laser-induced damage. HR (High-Reflectivity) coatings are widely applied in laser optics, such as for folding laser beam paths and laser cavity mirrors. ATOPTIK can provide dielectric mirror coatings with center wavelengths ranging from 250nm to 2200nm to meet customer requirements.

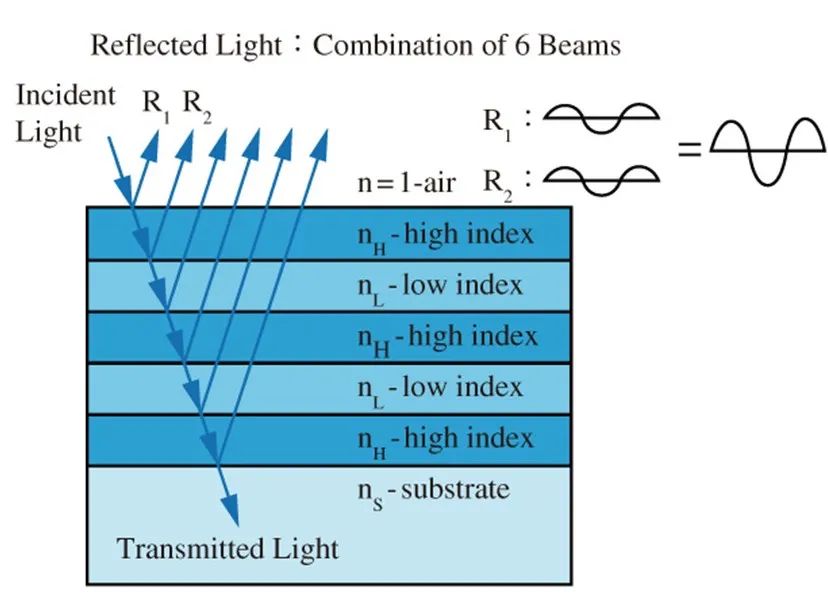

Dielectric-coated mirrors are created by depositing multiple layers of dielectric materials on the surface of an optical element. This layering causes interference and superposition of specific wavelength bands, thereby enhancing reflectivity. These mirrors offer high reflectivity and can operate across a wide wavelength spectrum. Since the dielectric coatings do not absorb light and are relatively hard and resistant to damage, they are well-suited for multi-wavelength laser optical systems. However, the thicker nature of the layers makes them angle-sensitive, and they are relatively expensive to produce.

High Reflectivity: Dielectric mirrors exhibit extremely high reflectivity within specific wavelength ranges. For example, in broadband dielectric-coated mirrors, reflectivity can exceed 99%, making them ideal for applications requiring efficient reflection, such as cavity mirrors in lasers and protective mirrors in high-power laser systems.

Low Absorption Rate: The use of multi-layer thin-film materials results in very low absorption rates for dielectric mirrors. This minimizes energy loss and thermal effects, enhancing system stability and longevity.

Wide Operating Temperature Range: Dielectric mirrors maintain stable performance across a wide temperature range, making them suitable for various environmental conditions, including extreme high and low temperatures.

High Durability: The multi-layer thin-film structure endows dielectric mirrors with high mechanical strength and chemical stability, enabling them to resist wear and corrosion and extend their service life.

Customizable Design: Dielectric mirrors can be customized based on specific application needs. By adjusting the number of layers and materials, optimized reflection can be achieved for different wavelength ranges. This flexibility ensures outstanding performance in various optical systems.

Low Scattering: Dielectric mirrors have exceptionally high surface flatness, effectively reducing light scattering and improving beam quality and transmission efficiency.

If you would like to build your own precision optical products or request a quote, please click one of the two buttons below. Otherwise, please fill out the form below with any questions or concerns.

Address

B3 Shengshi Shengshi Industrial Park,Auto-ETDZ, Changchun, Jilin, China

Call Us