In the intricate world of optical engineering, the quality of components is paramount to the performance of optical systems. ATOPTIK excels in this domain by employing advanced Cemented techniques to create high-quality Cemented lenses and prisms. These methods not only enhance the optical performance but also ensure the durability and reliability of the components.

Optical Cemented plays a crucial role in improving image quality, eliminating chromatic aberration, reducing light loss, enhancing imaging brightness, simplifying the fabrication of optical components, and protecting their surfaces. Two primary techniques are employed in optical Cemented: adhesive Cemented and optical contacting.

Adhesive Cemented: involves using optical-grade adhesives to join two or more lenses, prisms, or mirrors into a single optical element. This method is particularly effective for its versatility and the ability to meet precise technical requirements, such as ensuring centering errors or angular errors are minimized. The adhesive must meet stringent criteria, including high light transmittance, minimal shrinkage during curing, high mechanical strength, and excellent chemical and thermal stability.

Optical Cemented, relies on the molecular attraction between two polished surfaces to form a bond. This method is advantageous as it introduces no intermediary material, preserving the optical properties of the components. However, it requires high surface precision, making it suitable for large-diameter components and complex optical systems.

ATOPTIK specializes in producing high-quality Cemented lenses and prisms using both adhesive Cemented and optical contacting techniques. These components are meticulously crafted to meet the exacting standards required in various optical applications.

Process Stage | Technical Specifications |

Surface Preparation | Cleaning cemented surfaces, workstation setup, leveling table adjustment |

Quality Inspection | 6x magnification lens inspection under 68W-100W optical projector |

Adhesive Application | Bubble-free application with uniform layer distribution (0.1-0.3mm thickness) |

Curing Process | Primary: UV/High-pressure lamp curing (10-30min) |

Process Stage | Key Parameters | Technical Requirements |

Preparation | Thickness selection | • Chamfer cleanliness (Grade 0) |

Cleaning Protocol | Surface sequence | • Clean concave surface first |

Alignment & Bonding | Centration tolerance | • <5 arcmin alignment |

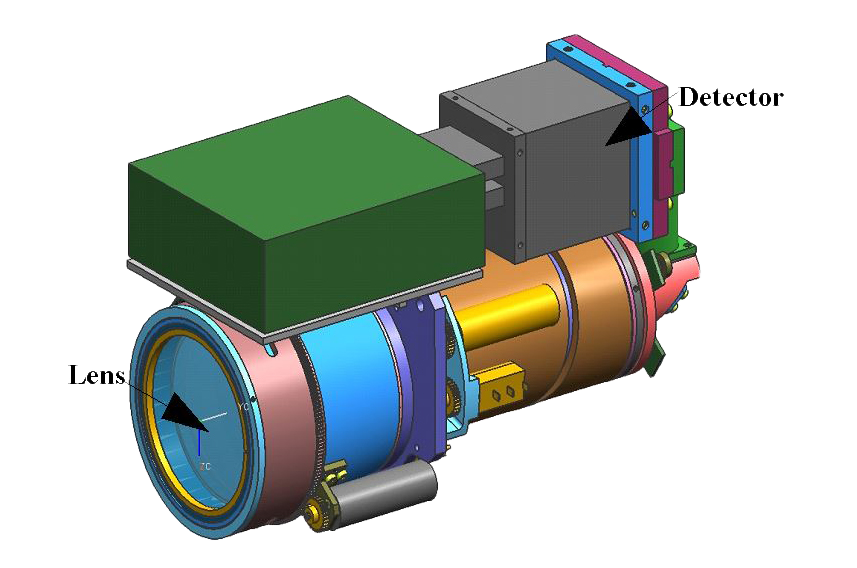

Enhanced Performance: Cemented lenses and prisms from ATOPTIK enhance the performance of optical systems by reducing aberrations, improving light transmission, and increasing overall system efficiency.

Versatility: These components are suitable for a wide range of applications, including imaging systems, laser technology, and advanced optical instruments, ensuring precision and reliability in diverse environments.

Durability:The Cemented techniques employed by ATOPTIK ensure that the components are durable, capable of withstanding various environmental conditions and mechanical stresses without compromising optical performance.

Conclusion: Precision and Reliability with ATOPTIK

ATOPTIK's advanced Cemented techniques for Cemented lenses and prisms exemplify the company's commitment to precision and quality in optical engineering. By leveraging these innovative methods, ATOPTIK continues to set new standards in the field, delivering components that meet the demanding requirements of modern optical systems.