Firstly, they increase the transmission of light through the optical components. By reducing the amount of light reflected at the interfaces of the components, more light can pass through, resulting in a brighter and more accurate image or signal. This is crucial in applications where every photon counts, such as in high - end imaging systems or low - light optical systems.

Secondly, AR coatings enhance the contrast of the image or signal. Unwanted reflections can cause ghosting and reduce the clarity of the image. By eliminating these reflections, ATOPTIK's coatings ensure that the image or signal is sharp and well - defined.

Finally, AR coatings help to improve the durability of the optical components. They act as a protective layer against physical and environmental damage, such as scratches and moisture. This means that your optical components will last longer and perform consistently over time.

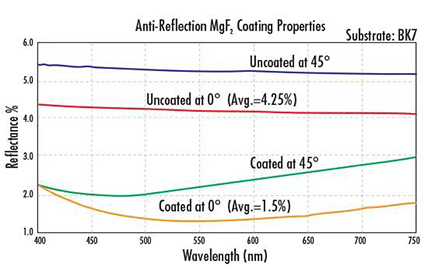

The science behind AR coatings is based on the principle of thin - film interference. When light passes through an optical component, a small percentage of the light is reflected at each interface. For example, when light passes through an uncoated glass substrate, about 4% of the light is reflected at each surface. This results in a total transmission of only 92% of the incident light.

ATOPTIK's anti-reflective coatings are designed to create destructive interference between the reflected light beams. The coatings have a specific optical thickness, which is usually an odd multiple of a quarter - wavelength. This causes the reflected light beams to be out of phase by 180 degrees, and they cancel each other out when they exit the surface. As a result, more light is transmitted through the component, and the reflections are significantly reduced.

The Durability of AR Coatings

Most of ATOPTIK's AR coatings are highly durable and can withstand physical and environmental damage. They are resistant to scratches, abrasion, and moisture, which makes them suitable for use in a wide range of environments. This durability ensures that your optical systems will continue to perform at their best over time, without the need for frequent maintenance or replacement.

The use of AR coatings is essential in many optical systems. In systems that contain multiple transmission optical components, AR coatings are crucial for reducing the cumulative effects of reflections. This can significantly improve the overall performance of the system, especially in applications that require high - precision imaging or signal detection.

Low - light optical systems also benefit greatly from AR coatings. By increasing the transmission of light, AR coatings allow these systems to capture more photons, resulting in a brighter and more accurate image. This is particularly important in applications such as astronomy, where the amount of available light is limited.

Coating Type | Wavelength Range | Key Applications | Performance Characteristics |

MgF₂ | ~550nm (broadband) | General optics | Low cost, simple structure |

VIS 0° | 425-675nm | Visible-light systems | 0.4% avg transmission improvement |

VIS 45° | 425-675nm | Angled optical systems | 0.75% avg transmission improvement |

VIS-NIR | Visible-NIR | Multispectral imaging | >99% NIR transmission |

Telecom-NIR | 1200-1600nm | Fiber optics, Data transmission | High-speed compatibility |

UV-AR | UV spectrum | UV spectroscopy | Enhanced UV performance |

UV-VIS | UV-VIS spectrum | Broadband analysis | Dual spectrum optimization |

NIR I/II | NIR spectrum | Laser systems, Fiber optics | High-precision NIR control |

SWIR | 900-1700nm | Industrial inspection, Security | Enhanced SWIR transmission |

In conclusion, ATOPTIK's AR coatings offer a wide range of benefits for optical systems, including increased transmission, enhanced contrast, and improved durability. With a variety of coating types to choose from, there is a solution for every optical application. Contact ATOPTIK today to learn more about our AR coatings and how they can improve your optical systems.

|

|

|

|

MgF2 | 400-700 | Ravg ≤1.75% @N-BK7 | 10 J/cm² @532nm, 10ns |

UV-AR | 250-425 | Rabs ≤1.0% | 3 J/cm² @355nm, 10ns |

UV-VIS | 250-700 | Rabs ≤1.0% (350-450) | 5 J/cm² @532nm, 10ns |

VIS-EXT | 350-700 | Ravg <0.5% | -- |

VIS-NIR | 400-1000 | Rabs ≤0.25% @880nm | 5 J/cm² @532nm, 10ns |

YAG-BBAR | 500-1100 | Rabs <0.25% @532nm | -- |

NIR I | 600-1050 | Ravg ≤0.5% | 7 J/cm² @1064nm, 10ns |

NIR II | 750-1550 | Rabs ≤1.5% (750-800) | 8 J/cm² @1064nm, 10ns |

Telecom-NIR | 1200-1600 | Rabs ≤0.25% (1295-1325) | -- |

SWIR | 900-1700 | Rabs ≤1.5% | -- |

This is the first one.